How do you guys usually mount or protect your digirig? Im running the armoloq frames on my manpacks and needed a way to mount the digirig that protects it. Just curious to see what you guys have come up with… Ive designed some cases and 3D printed some TPU cases… just curious what you guys have done.

I haven’t tried these, but I was planning to now that I have my battery:

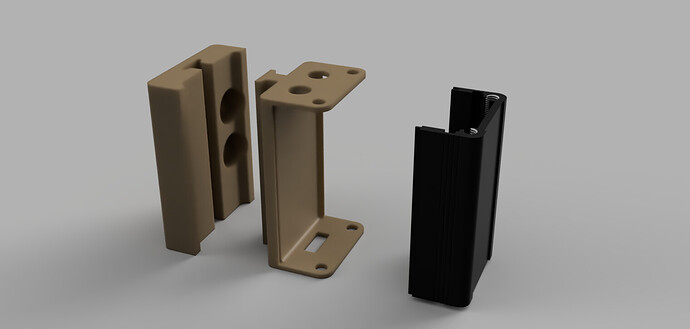

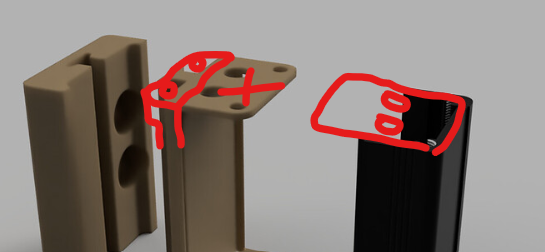

i like that… do a lot of people have external cases with equipment in them like that? I have a stack of cases in my garage/shop i usually make charger cases from (im in the drone hobby as well). Im playing around with this design now…

https://www.instagram.com/p/CnIEP0-vBX34tKvGckLJ5VL0pmxBQ_rRvXydy00/

im debating on adding cable reliefs as well, but trying to keep the bulk down.

I am glad you found the post helpful.

Portable, waterproof boxes with radio, battery, charger, speaker, external soundcard (if the radio lacks one), etc. are assembled by emergency communicators and called Go-kits, go-boxes, emcomm kits, etc. Winlink, NBEMS, sstv all require soundcards.

This link did not work for me…

I like it… never thought about a water proof box… I use a Mille bag and frames.

Very nice. Thanks for posting these photos here!!

I’m actually kinda curious why the form

Factor is so large. The case could be half the size honestly. You can almost fit two boards in the metal case.

Digirig started as a personal project without any ambitions for scale production so I’ve chosen a smallest off-the-shelve aluminum enclosure I could find. Now you can find some community contributions for smaller case designs.

Ohhh gotcha… I thought it was designed and made that way … hmmmm

I Velcro the Digirig to the radio or cabinet. The Digirig is plenty strong enough to stand on its own

agreed, but the form factor is literally 4 times the size as the board… which is fine… you can actually probably almost fit two in the case lol.

Im working/playing with ideas like this. PLA+, PTEG, carbon, or ABS… rugged utilized the metal half to hold and protect the board and a number of mounting systems. Im trying to get it as small and rugged as possible so it can easily fit in the manpack without bulk.

Nice… The only issue I see with this design is that connectors extend outside of the PCB on both sides and it will be a struggle to install/remove the PCB with end caps fixed in place.

I’ve thought about that, I’m hoping that the “flaps” are flexible enough to slide it on. If not ill add grooves to slide one side in. If that doesnt work i can make one end removable.

Right, the “struggle” part ![]()

Here’s an option: keep the stock ends at least on one side and use the empty space for mounting: something like a strap loop or snap clip.

lol yea, but show me a rugged anything that is easy to work with lol. I love the TPU holder for those who dont want to actually tear into the device itself but if someone wants a tiny device and are willing, you have to give up some level of “easy”. This will go through many variations, deletes, and rebuilds.

im usually designing full aircraft… working on the smaller stuff is actually more fun.

oh thats a good idea too…